This guide is here to help answer the age old question – What affects the cost of my custom tshirt order?

We actually get asked all the time what factors influence the prices of our screen printing service. We know money doesn’t grow on trees and, depending on what your shirts will be used for, sometimes you may be wondering what may help cut the cost of your order.

Well, rather than repeating ourselves (which we don’t mind – we love talking to our clients), we decided to write a guide that will decipher the complex science behind how screen printing companies come up with that crazy figure on the bottom of an estimate. We’re just kidding – it’s not that complex – in fact, it’s really simple once you know what you’re looking for.

And don’t worry – we’ll keep the terminology and custom apparel lingo down to a minimum.

Each silk screening company has their own way of breaking down their pricing but there are certain factors that every screen printer takes into consideration when pricing a job.

The Color Factors

Color Factor 1 – The color of the shirt or garment you’re looking to print on.

White shirts will be your cheapest option when it comes to shirt color. The darker the shirt gets, the more expensive it gets. So, a black shirt will usually be at the top end of the pricing scale. Most other shirt colors will fall somewhere in between white and black when determining price, however, some darker colors like red or dark blue will be priced at the same level as a black shirt.

Color Factor 2 – The amount of colors in your design that will be printed on the garment

The more colors that get printed on a shirt, the more costly your job will become.

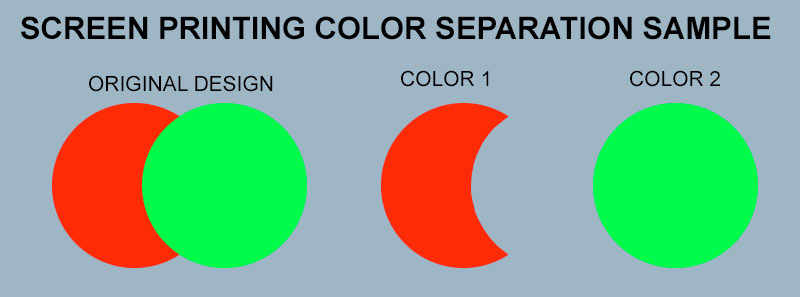

To print your design onto a shirt, the printer will need to take your design and separate and isolate each color.

While we don’t want to bore you by detailing the entire process, the main thing to take away is each color is independent of each other and printed onto the shirt separately, which translates to the printer having to utilize more materials and labor.

This is the reason why DTG (Direct To Garmet) printers are becoming very popular in the industry, but there are still drawbacks to using a DTG printer.

Type And Quality Of The Custom Apparel Products

Not all products are created equally and it’s the job of the company you’re working with to understand what you’re looking to accomplish and give you the best product that will achieve your goals.

Clients who are using shirts as a promotional tool may opt to go with a lighter weight (5 oz vs 6 oz) shirt. By going with a lighter weight shirt, their job may not cost as much but they still have a great product to promote their business.

The next question you’re probably wondering is: Are 5 oz shirts a bad product to get? The answer is no.

While it may seem a like a dramatic difference, it really isn’t. But then again, that’s why it’s important the company you’re working with has both: 1) an intimate knowledge of the products they offer and 2) they completely understand what you’re looking for and trying to accomplish.

The “style” of your shirt will also play a factor into pricing. Standard “T-Shirts” will usually be your most economical choice, however, we know a lot of times that will not fulfill what you’re looking for. Styles like tank tops, V-Neck shirts, scoop neck, etc will usually cost a little more.

Check out this video from the Wall Street Journal which highlights the difficulties in searching for the perfect t-shirt or you can read more about it here.

Quantity Of Shirts

Similar to the concepts of Sam’s Club and Costco, the more garments you order (at one time), the better ‘price per shirt’ cost you will get. Each company has their own set of “minimums” they require from their clients.

With us, there are no minimums but the more pieces you order, the more we’re able to lower the price. A good starting point is 24 pieces, however, we have people who order 5 or 10 shirts from us all the time. Bulk pricing usually starts at 144 pieces and above.

Apparel Sizes

We do shirts for a lot of youth sports teams and organizations and buyers are constantly surprised that the cost of youth apparel is typically more than adult sizes, especially with shirts. Most people think “youth sizes are less fabric and therefore should be cheaper.” While that seems logical, believe it or not, youth shirts are generally more expensive than adult sizes.

On the other end of the spectrum, sizes such as 2X-Large and above are referred to as “extended sizes”. Extended sizes, depending on what type of garment you’re getting, will cost you a little more per piece.

Garment Fabric

The most economical shirts you’ll get will usually be cotton – either 100% cotton or a blend of cotton and another fabric. These are also the most popular items to get screen printed.

However, if you’re looking for a special fabric, such as moisture wicking, nylon, etc. then that will cost more.

Print Placement

Normally, the standard print areas for shirts include the center front of the shirt (including a “pocket” print which is on the left chest) and the center of the back part of the shirt.

Some companies consider printing on a sleeve to be special placement so it’s best to check with whoever you’re working with and find out. We consider sleeve prints as a standard print placement with no extra charges to the customer.

Some clients are looking to print on other parts of the shirt, for example, right under the neckline, on the side of the body, etc. Most companies will charge a little extra, per piece, to print in these locations because it takes a little more time to print. A company may claim they do not charge for ‘specialty print locations’ but they’re just adding this fee to another part of your order.

Types Of Inks Used (Specialty Inks)

Specialty inks, such as shimmers, glitter, etc. will add some costs to your order. Also things like rhinestones or other similar materials will cost more than your standard inks.

Artwork

This is another factor where clients may get caught off guard.

Most times, people have a pretty good idea of what they want and will even have artwork they found on the internet or something done by a graphic artist.

Artwork Myth 1 – I’ll just use what I found online and put that on a shirt

Okay, you’re excited because you’ve found something online and want put that on a shirt. We promise not to get too technical on you but there is a motto screen printers follow called “GIGO” (Garbage In Garbage Out). If you’ve pulled something from online, it is most likely going to be “low resolution”. Simply put, it means the resolution is too low for us to effectively print it on a shirt. If we “enlarge” your picture, design, etc. to make it big enough to print on a shirt, the design will become ‘grainy’ during the enlarging process.

Can we put it on a shirt? Sure, but short of enhancing it through software, it most likely won’t come out as crisp and clear as you ‘d like. The graphic may appear “fuzzy” and there’s a good chance you won’t be happy. It’s very easy to put a low resolution image onto a shirt on a computer screen and email it to you as a proof. Sure, the shirt will look flawless on your computer screen but don’t expect the same quality on the finished product.

The good news is there are things we can do to help make your design better but keep in mind if you start with a small, low resolution graphic that it will never be that same quality on a shirt.

Artwork Myth 2 – My graphic designer knows how to design artwork for screen printing

While graphic artists wear many hats and are proficient at many things, unless they specifically know the inner workings of how screen printing works, they may not know all the fine details that will make your design pop on a shirt.

Printing on garments is not the same as printing on a flyer, brochure or business card.

The reason we’re mentioning this is because clients are surprised they need to have additional artwork done to their files – which adds to the cost.

Sure, the more you can give us and the less time we have to spend to get your files print ready will definitely minimize the time (and associated fees) necessary to get your files print ready. However, if your artwork file is not print-ready for garment printing, then you should keep in mind that the printing company will need to spend some time to prepare your files so they are print-ready, which will add to your costs.

Screen Printing Set Up Fees – What Are Those Anyway?

The basic premise of screen printing is pushing ink through a mesh screen onto a garment, like a t-shirt, towel or bag.

When a company talks about “screen set up fees,” they are referring to the process it takes to get the actual screen ready so they can put that on the press to make your shirts. While not getting into too much detail on what the entire set up process entails, they basically need to:

• Prepare the screen so they can ‘expose’ your designs onto the screen

• Actually expose your design onto the screen

• ‘Reclaim’ (or clean) the screen after it’s done

Remember, as stated above, screen printing requires each color to be separated so if you have a 5 color design, then the company will need to make 5 screens (1 screen per color). It takes materials, labor and time to complete the entire process which is why companies charge customers for this.

Some companies will advertise “No Screen Set Up Fees”. That’s fine and dandy but 9 times out of 10 they’re making it back somewhere else. The only time you’ll avoid these fees outright is if you order a large quantity (bulk order), which will vary from company to company.

That’s It Folks

We hope this helps explain some of the factors companies use to determine how much your job will cost. If you have any comments or questions about our screen printing services, please drop us a line.